Laboratory

Facilities

Facilities available at the DIMMALab include equipments to meet the special requirements for the research and development of metal and ceramic materials but also for composites, polymers, metal foams, functionally graded materials (FGMs), hard metals and coatings, and nanomaterials.

Our facilities include:

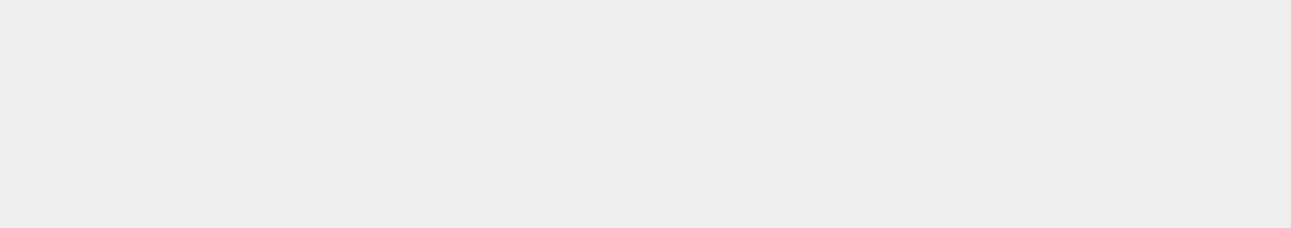

Spark Plasma Sintering Equipment type KCE®-FCT HP D 10 for consolidation of various powdery raw materials by using uniaxial pressing force and heating by direct current supply (DC impulses) up to temperatures of 2400°C. The whole process can be run under vacuum as well as under inert atmosphere (N2, Ar) to sinter powders.

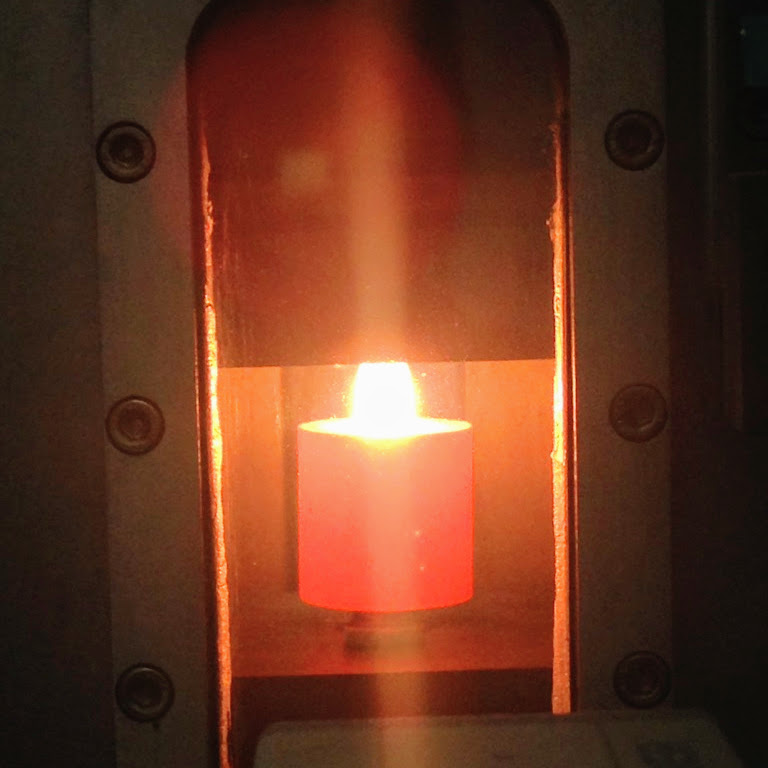

Powder preparation equipment: 2 planetary Mills, a Turbula T2F, vibratory sieving equipment SS3 press of 20 Ton, glove box with controlled atmosphere to work in argon or nitrogen atmospheres, analytical balances, and 2 drying ovens.

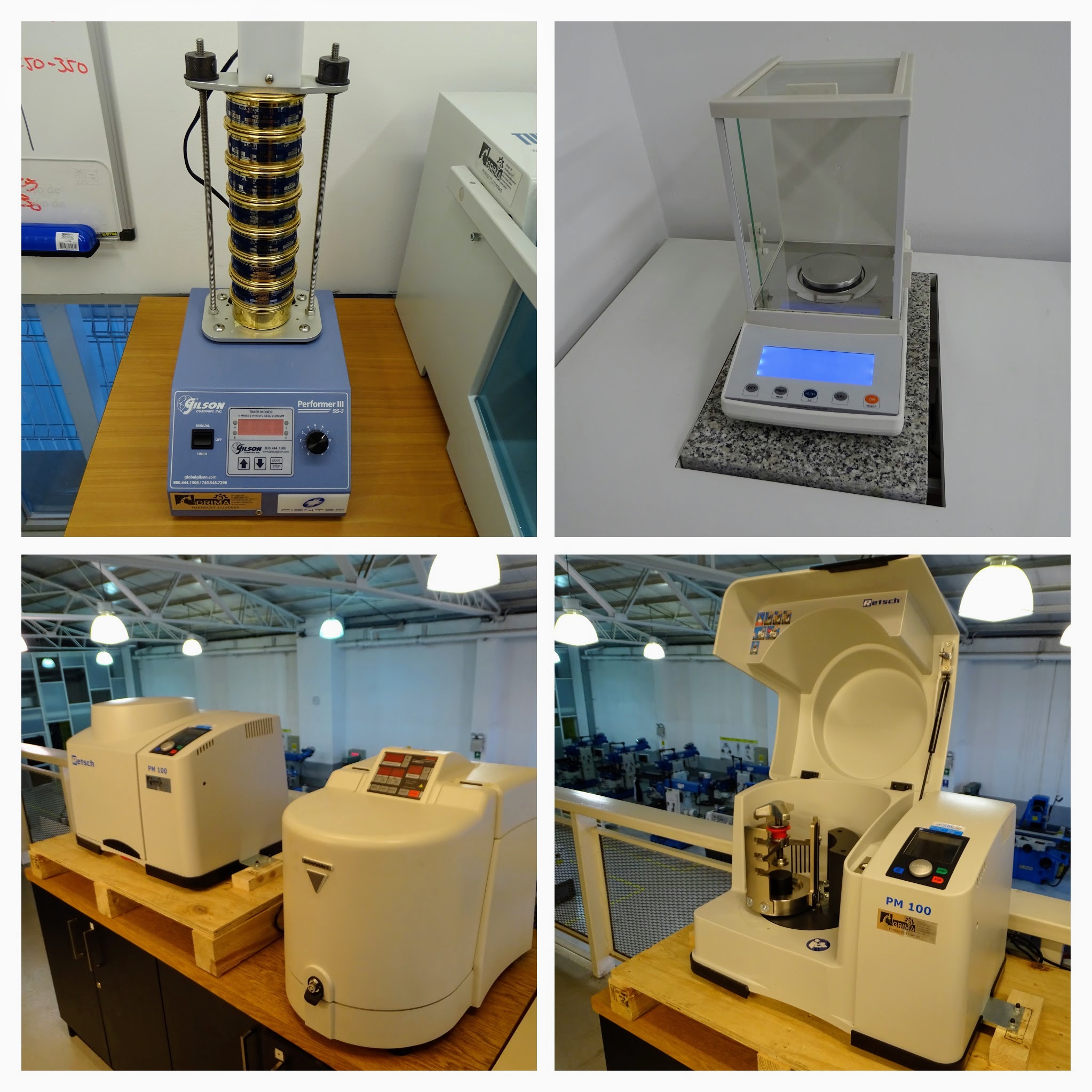

Laser cutting equipment Trotec Laser Speedy 400 and 3D printing equipment.

Mechanical shop laboratory: In this laboratory, the tools and materials necessary for the maintenance and reparation of some equipment required during the project are available, such as the CNC (Haas) machine and the pro-engineering software used to design mechanical parts.

Other facilities available at the Mechanical Engineering Department and Metallurgical and Materials Engineering Department:

Microstructural characterization laboratory: manual and automatic polishers (Presi), Press mount specimens (Presi), Specimen cutting machine (Isomet), Atomic absorption spectrophotometer Shimadzu AA 6800, Scanning electron microscopy (SEM) EVO Carl Zeiss and X-Ray diffractometer STOE STADI MP.

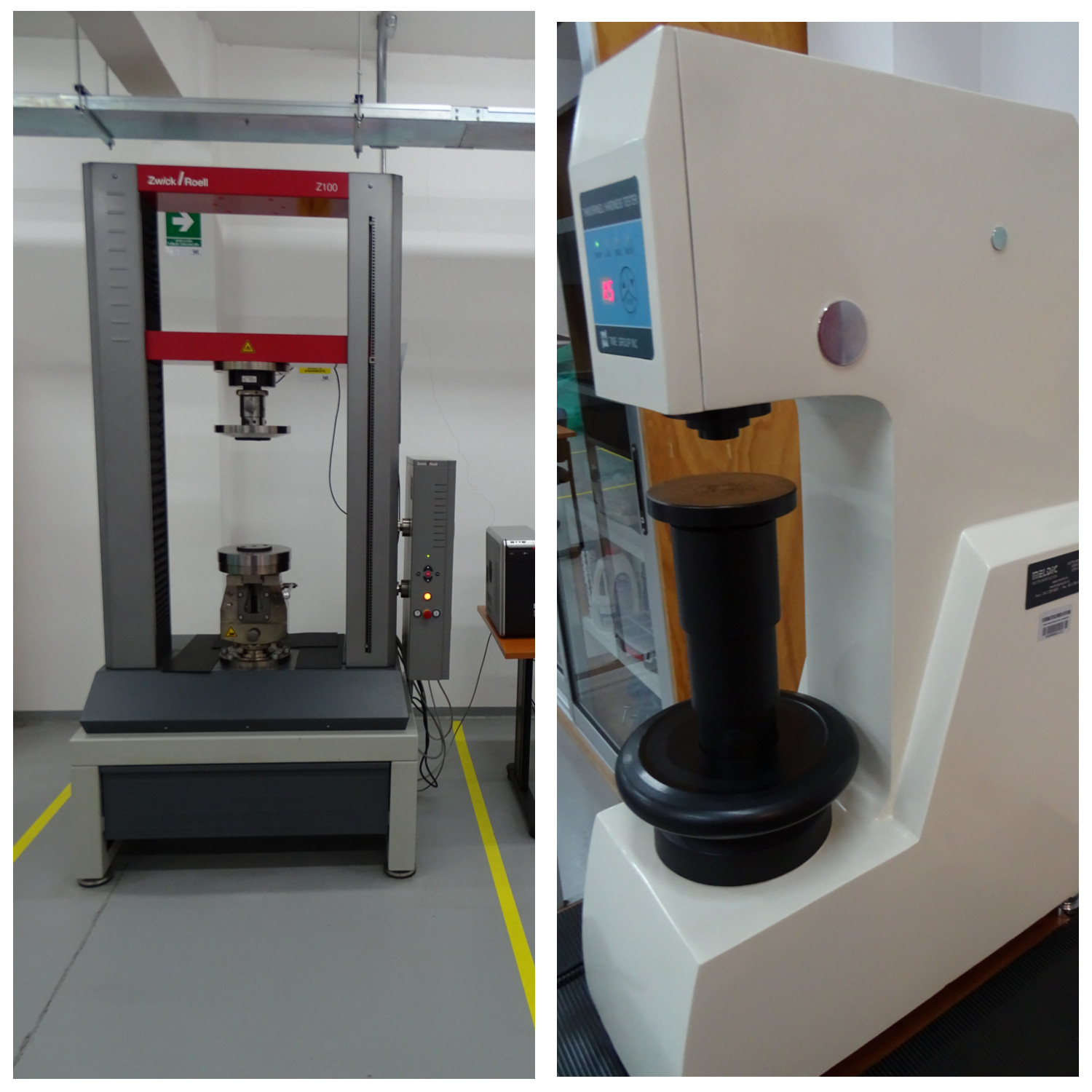

Mechanical testing laboratory: Accessories for Archimedes´ measurement, Zwick Roell universal testing machine for mechanical testing (4 and 10 Tons), conventional hardness testing machines (Rockwell, Brinell).

Team Members

Current Lab Members

Sheila Lascano Farak

Principal Investigator

Dr. Lascano joined the Mechanical Engineering Department at Universidad Técnica Federico Santa María (UTFSM) in 2012 and directs the GRIM3A since its creation in 2017. Prior to joining UTFSM, Dr. Parra was professor and researcher in Universidad del Norte (Barranquilla-Colombia). Dr. Mechanical Engineering Uninorte (2012).

sheila.lascano@usm.cl

Mauricio Reyes Valenzuela

Research Assessor

B.S. Mechanical Engineering, Universidad Técnica Federico Santa María (2017).

Ricardo Chávez Vásconez

B.S. Mechanical Engineering Escuela Politécnica Nacional, Quito-Ecuador(2017). Doctoral Student Universidad Técnica Federico Santa María, M.S. Student Universidad Técnica Federico Santa María, Valparaíso-Chile

Sergio Sauceda Martínez

B.S. Mechanical EngineeringUniversidad Michoacana San Nicolas de Hidalgo, Morelia-México(2018). M.S. Student Universidad Técnica Federico Santa María, Valparaíso-Chile

Claudio Aravena

Technical Assistant

Tecnico Universitario en Diseño y Fabricación de Matrices y Moldes, Universidad Técnica Federico Santa María, Valparaíso-Chile (1997). Technical staff, Mechanical Engineering Department, Universidad Técnica Federico Santa María

Ignacio Gonzalez

Research Assistant

M.S. Student,Universidad Técnica Federico Santa María, Santiago-Chile.

Yerko Espinosa Maldonado

Research Assistant

B.S. Student, Mechanical Engineering Universidad Técnica Federico Santa María, Santiago-Chile.

Felipe Benitez Maldonado

Research Assistant

B.S. Student, Mechanical Engineering Universidad Técnica Federico Santa María, Santiago-Chile.

Gabriel Sanllehi Oyanedel

Research Assistant

B.S. Student, Industrial Mechanical Engineering Universidad Técnica Federico Santa Maria.

Ingrid Godoy Ramírez

Administrative Assistant

Mechanical Engineering Department, Universidad Técnica Federico Santa María, Santiago-Chile.

Former Lab Members

Daniela Muñoz

B.S. Mechanical Engineering, Universidad Técnica Federico Santa María (2015). Currently at Maintenance Engineering in Sanitarias IV and V region, Chile.

Viviana Mardones Echeverría

Universidad Técnica Federico Santa María (2016). Currently at Codelco, Radomiro Tomic, Calama, Chile.

Jorge Maluenda Cáceres

B.S. Mechanical Engineering, Universidad Técnica Federico Santa María (2018)Currently at Komatsu Reman Center Chile (Antofagasta).

Raymundo Valverde Veloso

B.S. Mechanical Engineering, Universidad Técnica Federico Santa María (2019).

Opportunities

Design and prototyping of a porous dental implan.

Development of bioactive coating and biological response in TiNbTaMn alloys for biomedical applications.

Design and prototyping of in vitro system to perform tensile tes.

Characterization of mechanical behavior of hard coatings obtained by thermal spraying.

Design and development of porous media for combustion.

Improvement of solar cells panels using highly porous thermal cooling system.

Labs news and events

Visit of ASMAR, June 2019, Valparaíso-Chile.

Raymundo Valverde presentation to obtain B.S. in mechanical Engineering.

I Workshop nanotechnology, advanced manufacturing and industry, 2019. See more.

Participation in Computational Mechanics Congress in Punta Arenas, Chile. Ignacio Gonzalez.

Eduardo Mödinger presentation to obtain B.S. in mechanical Engineering

Visit to Universidad de Concepción, Chile to interact with the research group of prof. Mangal.

Sergio Sauceda does his thesis in komatsu.